TinyBoy (TM) 2 L10/L16 Assembly Guide v0.99c

This is the assembly guide for TinyBoy(TM) 2 L10 version.Your DIY kit may be a little bit different as different slots of parts from the factory may be a bit different.

Preparing the case

This is the plates for the case. Let's do the preparation. First, please take off the protection paper from the plates.

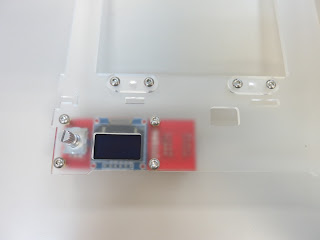

Then, please do the following of the photos.

For Side 1

Preparation of the cables of the connection board

Please don't trust what had been written on the board, just follow the following photo. Please mark the sockets and plugs by yourself.

For Side 2

For Side 3

For the Top Side

For the Bottom Side

OK, we are now done. Then, let's join the case together.

Before we start, please aware for the joints. Don't screw too hard as the plate is quite easy to be broken as the joints are weak.

Be careful! It is weak. Don't Hard screw. Just Soft screw when it just enough.

Be careful! It is weak. Don't Hard screw. Just Soft screw when it just enough.

Be careful! It is weak. Don't Hard screw. Just Soft screw when it just enough.

Be careful! It is weak. Don't Hard screw. Just Soft screw when it just enough.

Please follow the video to join the plates to form the case.

Prepare for the X module.

You are now in the half way. At this moment, we are going into a important part, to build the X module.

Please Put oil on to the Rods 1st.

Preparing the Y module

We are now going to work on the Y - Axis part.

Putting the Y module into the machine.

Please Put oil on to the Rods 1st.

To adjust the Y platform, screw out a bit of the middle screw, push the platform to the left side, the screw it back. Then, do the same way with the right side.

Preparing the Z module

Putting X module into the machine

Please Put oil on to the Rods 1st.

To do the Z rod Adjustment, please hole the X module as the following, and then screw the top screw of the triangle.

Then, the adjustment is finished. The x module should be very smooth like a Guillotine.

To adjust the Z rode,

Then, put the long screw onto the Z module

Preparing the Extruder

And Put the Extruder onto the machine under the hole of the fan.

Preparing the hot-end and put it into the X module

From the left: Heater socket, Temperature sensor socket, Fan socket.

Warning: Please make sure the sensor cable and fan cable are not swap. Otherwise the fan socket will be short circuit.

Put it onto the X module

Wire Connection

Hi. I just assembled the J10. Presumably an earlier version than the L10? In any case, here are my comments, mostly regarding where things differed from the instructions above:

ReplyDelete* Would be great if the sides were labeled (front, left, right, back, bottom, top)

* Would be great if there were a chart showing the various screw sizes with a label for reference on the few occasions where a different size screw is used. (I appreciate the extra screws in the package as children will lose them.)

* Before assembling the box, it is probably easier to have put all of the components that come out of the sides in place.

* Looping the cable ties through but not tightening them before assembling the box makes it much easier.

* You need to add the molex to the button on the bottom plate before assembling the box.

* You need to run the motor cable from the horizontal axis through the hole in the corner of the bottom plate before assembly (or enlarge the hole) since the connector is too big to pass through.

* It is not clear how the "adjustable" holes for the rods can be adjusted.

* It is not clear how much slack to leave in the cables attached to movable elements.

* Where does the lovely TinyBoy 2 Plexiglas label get mounted?

* The motherboard should not be mounted until the end, since you need to fit other parts around it and to screw in wires.

* I had to use another J10 to figure out how to do the wiring as the layout is quite different.

It passed the smoke test. Next calibration. (I need to get some filament before I start printing.)

It has been really fun so far. Thank you.

Actually, base on the some testing record and information in the pass. We found out we need one machine that should met these below, reasonable buffer and practical printable gross area ratio, a common public acceptance factor of safety, highly reliable, can be operate under the reasonable maintenance, make most of the parts are available to open. According to the above requirements, there are some major model change, a true Junior version to everyone, the J10, the laster version, the J10 is improving the the inner wire system, power supply changed, but there have to finish the fully pressure, loading, stability, A sufficient numbers printing test to prove the practical failure rate. Thank you for support TinyBoy Project

DeleteWhat a useful pictorial! I think now not only electronic engineers but others would also make it so easily. Thanks for sharing your step to step pictorial.

ReplyDeleteGreat pictorial tinyboy. You have been doing good.

ReplyDeletePunjab FCi Examination is to be announced soon too

ReplyDeleteGood one guide. However, it is necessary to find out all of the things that can lead to a successful toy making effort. Being a coursework writing services provider, I must appreciate this.

ReplyDeleteThis is actually a very informative article – not like most of what I see online. Thanks for the free share and looking forward to reading your updates! simply wow

ReplyDeleteWebroot Support | Canon Printer Support | Brother Printer Support | HP Printer Support

Thankful for putting aside the push to explore this, I feel significantly about it, and I value getting comfortable with it. If possible, when you make understanding, OK want to invigorate your blog with more information? It's really significant to me. Website: Printer Not Activated Error Code 41

ReplyDeleteAdvertisers bid on keywords that are usually used by the users in order to search for something. PPC Services greatest strength is that it creates an opportunity for the advertiser to showcase to their ads to the motivated customers who have the potential and will of making on the spot purchase. PPC Company in India

ReplyDeleteAccording the to "MBA Thesis writing service in Lahore"This kinds of activities is really good and helpful for the enhancement of students knowledge and skills of their knowledge and skills, and these kinds of science project should every students have to do it for their own sake.

ReplyDeleteIts better to provide knowledge of excellence and familiar students with upcoming technologies and graduate them with skills to survive in a professional world. Cheap Assignment Writing Service UAE also encourage students and provide a platform to interact.

ReplyDeleteThe choli of the lehenga is a mix-match collaborative where an Anarkali style broadening and pleated/ non-pleated kurta is combined with a lehenga bottom. Buy, heavily embroidered bridal Anarkali lehenga that can be customized in any colour of your choice with Panache Haute Couture.

ReplyDeleteHey, That's an amazing project. I am a writer and assist students by providing Cheap Assignment Writing Service In UAE. If you ever need any help with you assignments let me know. I am the besst assignment writer in UAE.

ReplyDeleteThe ardent Programming Homework Help tutor that nailed down my project was very passionate. He answered my Python questions with long, self-explanatory solutions that make it easy for any average student to revise. Moreover, he didn't hesitate to answer other questions, too, even though they weren't part of the exam. If all Python Homework Help experts can be like this then they can trend as the best Programming school ever

ReplyDeleteHi, other than economics assignment help are there other subjects that you cover? I am having several assignments one needs an economics homework help expert and the other one needs a financial expert. If you can guarantee quality work on both then I can hire you to complete them. All I am sure of is that I can hire you for the economics one but the finance one I am not sure.

ReplyDeleteHey there, I need an Statistics Homework Help expert to help me understand the topic of piecewise regression. In our lectures, the concept seemed very hard, and I could not understand it completely. I need someone who can explain to me in a simpler way that I can understand the topic. he/she should explain to me which is the best model, the best data before the model and how to fit the model using SPSS. If you can deliver quality work then you would be my official Statistics Assignment Help partner.

ReplyDeleteVisit:https://www.statisticsassignmentexperts.com/

The Industrial Oils Market is estimated to account for a value of USD 60.2 billion in 2019 and is projected to grow at a CAGR of 5.0% from 2019, to reach a value of USD 80.7 billion by 2025. The biodiesel industry is projected to be a major revenue generator for industrial oils manufacturers in the coming years due to its reduced environmental impact. In addition, the industrial sector in the emerging countries of the Asia Pacific region is growing with countries such as China and India, which are the hub of industrial oils, due to the expanding chemical, biodiesel, and cosmetics industries.

ReplyDeleteNice blog.

ReplyDeleteGlobal electronic sphygmomanometer market is anticipated to grow at a CAGR of 8.2% by 2023

The information you provided is very useful, thank you very much for sharing useful information with us. You can apply for an online Turkish visa - If you are Planning a Trip to Turkey for tourism, business purposes. You can fill the e visa of Turkey application form in less than 5 to 10 minutes.

ReplyDeleteMIG welding is capable of high productivity but the quality of welds can be called into question. https://www.powertoolsreport.com/

ReplyDeletehttps://www.powertoolsreport.com/best-mig-welder-under-500/

https://www.powertoolsreport.com/best-mig-welder-under-1000/ Here's you can review the latest articles on this niche.

Mulberry trees grown from seed can take up to ten years to bear fruit. mullberry bush monkey weasel Mulberries are most often planted from large cuttings, which root readily. The mulberry.

ReplyDeleteWow.. Very informative article thanks for sharing please keep it up.. Pakistan visa on arrival gets online via the Pakistan visa website.

ReplyDeleteI appreciate this article for the well-researched content and excellent wording and looking forward to gaining the most prospective results. If you want to stay connected with our affirmative, then you can come to our education dashboard panel to check out how to write accounting research topics.

ReplyDeleteIn education, a project is a collaborative process that is carefully organised to attain a certain learning goal. It typically involves several teachers and educational professionals.

ReplyDeletefundamentals

For the first time in a long time, I read a really amazing and truly vital post. It is my pleasure to inform you that if you are planning to travel to Turkey, a Turkish evisa is the best option for getting a visa because of its easy process and reduced cost and time.

ReplyDeleteDo you like dark flower agate? Flower Agate is a mineral that symbolizes emotional development. Flower Agate is also known as Blossom Agate, Blossom Jasper, Sakura, or Cherry Blossom Agate.

ReplyDeletemeanwhile, continue to pour billions into their AI infrastructure.

Delete휴미추천업소

쩜칠추천업소

프리덤추천업소

불밤추천업소

궁합추천업소

찰덕궁합추천업소

토끼추천업소

샤쿠미추천업소

불밤추천업소

달새추천업소

Uphold.com Login

ReplyDeleteNavigate to the closest grocery Store can be a daunting task for many people. With the help of this comprehensive guide, you can find the best deals and services near you with ease. This guide will provide you with tips on how to use GPS technology, online search engines, and other methods to locate the best grocery stores in your area. It will also discuss how to compare prices and services of different stores in order to get the most value for your money. Finally, it will provide advice on how to take advantage of special offers and discounts that may be available at certain stores. With this guide, finding the perfect grocery store near you has never been easier!

ReplyDeleteQantas Airlines

ReplyDeleteGet the best odds and betting options on cricket with our safe and reliable service. Online Cricket betting ID|

ReplyDeleteDLF The Dahlias is an exclusive luxury residential project situated in DLF Phase 5, Gurugram. Designed with a focus on sophistication, privacy, and premium living, this enclave offers an ideal combination of modern conveniences and serene natural surroundings.

ReplyDeleteDLF The Dahlias

Ledger.com/start provides unmatched security by keeping your private keys offline. With its advanced encryption and user-friendly interface, Ledger wallets cater to both beginners and experienced investors.

ReplyDeleteLedger hardware wallet is easy. Simply go to Ledger.com/start, follow the step-by-step instructions, and install the Ledger Live app to manage your cryptocurrencies safely. This user-friendly platform supports a wide range of digital assets, providing seamless transactions with full control over your investments.

ReplyDelete

ReplyDeleteThanks for sharing with us. With a legacy of delivering iconic projects, DLF New Launch is set to become a benchmark in luxury real estate. Whether for investment or self-use, this project presents a rare opportunity to own a home in a meticulously planned, high-end community. Experience the epitome of elegance and comfort with DLF’s latest masterpiece.

Atomic Wallet is available for Windows, macOS, Linux, Android, and iOS, ensuring accessibility across all major devices. The user-friendly interface makes it ideal for both beginners and experienced traders. No registration or KYC is required, ensuring privacy and anonymity.

ReplyDeleteI’ve used a few academic services in the past, but most felt like templated work. This one stood out because Ryan (yeah, a real guy) explained the logic behind the code I asked for. Got Assignment Help Online but also learned how the algorithm worked, so double win honestly.

ReplyDeleteTight deadline? Professional Assignment Help delivers fast, accurate solutions so you never miss a due date. Save time and reduce stress—try it today and experience stress-free academic success!

ReplyDeleteProgramming and data structures are tough to master without guidance. With Computer Science Assignment Help, students receive expert support in Python, Java, AI, and algorithms to meet deadlines and boost coding accuracy.

ReplyDeleteThanks for sharing this valuable post! Finding accurate and complex CHCCOM003 assessment answers can be really challenging, especially with the detailed communication strategies required in community services. This kind of guidance is incredibly helpful for students trying to understand the practical applications of effective communication in real-world scenarios. Having access to expert support makes the learning process smoother and more efficient.

ReplyDeleteGreat blog! The insights on Java Assignment Help Online are truly helpful for students struggling with complex coding tasks. As someone who faced challenges with Java loops and OOP concepts, I found online help services to be a lifesaver. Getting expert assistance not only improved my grades but also enhanced my coding skills. It's amazing how these platforms provide timely, accurate, and plagiarism-free solutions. Thanks for shedding light on such a valuable academic resource for programming students!

ReplyDeleteHowever, overall sales in China shrunk compared to a year ago, with the company generating

Delete휴미추천업소

쩜칠추천업소

프리덤추천업소

불밤추천업소

궁합추천업소

찰덕궁합추천업소

토끼추천업소

샤쿠미추천업소

불밤추천업소

달새추천업소

Our online philosophy assignment help is ideal for students seeking flexible, high-quality support. We cover a wide range of topics, including ancient philosophy (Plato, Aristotle), modern philosophy (Kant, Descartes), existentialism (Sartre, Nietzsche), ethics, logic, and political philosophy. Our experienced writers, many with advanced degrees in philosophy, deliver customized solutions that align with your course objectives and academic standards. From essays and research papers to critical analyses and reflective journals, we ensure your work is original, logically structured, and thoroughly referenced using credible sources. With our online philosophy assignment help, you gain access to expert guidance that simplifies complex ideas. We break down abstract concepts into clear, concise arguments, helping you develop a deeper understanding of philosophical texts and theories. Our online philosophy assignment help platform is user-friendly, allowing you to submit requirements, track progress, and communicate with writers anytime, anywhere. We prioritize confidentiality, timely delivery, and plagiarism-free content to meet your academic needs.

ReplyDelete

ReplyDeleteTrezor.io/start – Secure Your Crypto with the #1 Wallet

Trezor is more than just a hardware wallet—it’s a secure gateway to the blockchain world.

Developed by SatoshiLabs, Trezor introduced the first-ever hardware wallet in 2014 and has since become a trusted name among crypto holders.

It stores your private keys offline, completely isolated from internet-connected devices, making it virtually immune to hacking and phishing attacks.

Trezor.io/Start

Great content! I was looking for a way to find someone's RUT for a business contact in Chile, and rutificador was exactly what I needed. Your breakdown helped me avoid unreliable websites. Super useful for professionals working with Chilean partners.

ReplyDeleteThursday’s results paint an early picture of iPhone sales since its fourth quarter ended on September

Delete휴미추천업소

쩜칠추천업소

프리덤추천업소

불밤추천업소

궁합추천업소

찰덕궁합추천업소

토끼추천업소

샤쿠미추천업소

불밤추천업소

달새추천업소

ReplyDeleteTrezor.io/start is your official gateway to setting up the world’s most trusted hardware wallet—Trezor®. Designed to offer unmatched security, Trezor ensures your crypto assets stay safe from hacks, phishing, and malware. Whether you're a beginner or experienced user, the setup process is simple and guided step-by-step. By following Trezor.io/start, you can activate your device, install Trezor Suite, and begin managing your Bitcoin, Ethereum, and other digital assets with confidence. Don't risk your funds on insecure platforms—choose Trezor and take control of your crypto journey with the best in cold storage technology.

Trezor.io/Start

Tired of juggling multiple subjects and tight deadlines? With expert support, Assignment Help Western Australia simplifies your workload and enhances learning. Take control of your academics and submit flawless work!

ReplyDeletedemand for the iPhone 17 lineup, which Apple launched in late September.

Delete휴미추천업소

쩜칠추천업소

프리덤추천업소

불밤추천업소

궁합추천업소

찰덕궁합추천업소

토끼추천업소

샤쿠미추천업소

불밤추천업소

달새추천업소

Wellness enthusiasts consider cupping therapy in bangalore to be a vital addition to their self-care routine, offering a holistic and natural way to maintain body balance.

ReplyDeleteABC, Disney Channel, FX, National Geographic and Freeform.

ReplyDelete휴미추천업소

쩜칠추천업소

프리덤추천업소

불밤추천업소

궁합추천업소

찰덕궁합추천업소

토끼추천업소

샤쿠미추천업소

불밤추천업소

달새추천업소

Access your USAA Bank account easily through the USAA Bank Login (**) page. Securely access your crypto portfolio with the BlockFi Login (**). The Coinsquare Login (**) portal lets you buy, sell, and track your portfolio anytime with confidence and ease. Metamask Login (**) allows users to securely access decentralized applications (dApps) using their crypto wallet. Netcoins Login (**) provides users with secure access to their cryptocurrency trading accounts.

ReplyDeleteThat’s such an interesting topic to explore! If you’re someone who enjoys testing your luck, checking the latest mega millions winning numbers can be an exciting way to stay updated and inspired.

ReplyDeleteI've always struggled with managing multiple deadlines, so I eventually turned to Native Assignment Help just to survive the workload. I didn t expect it to make such a huge difference, but it honestly did. They helped me get my workload under control and, for the first time, actually understand what each assignment was asking for. Later, when my supply chain coursework started getting tougher, I tried lidl supply chain, especially understanding how Lidl manages global sourcing, lean procurement, efficient inventory turnover, and cost-effective logistics compared to competitors, and it honestly became a complete lifesaver. Instead of feeling overwhelmed by criteria, units, and endless task requirements, I finally had someone guiding me through everything in a way that actually made sense.

ReplyDelete